THE OBTECT

WHY

THE OBTECT

DEVELOPED

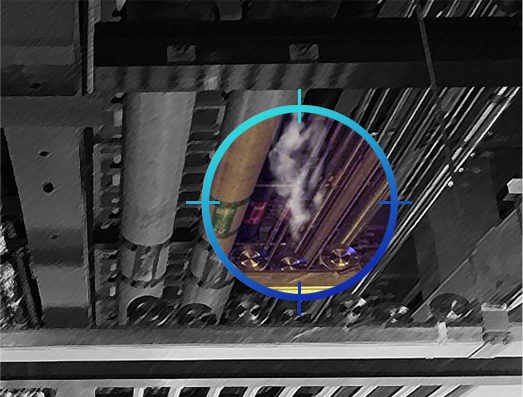

Many hazardous chemicals are used in semiconductor and display manufacturing processes, and countless pipelines are used to supply chemicals to various manufacturing equipment.

The inside of these pipes can be corroded by harmful chemicals, and the most vulnerable place is the "pipe connection part" that changes the

direction or lengthens the pipe.

To this connection, an O-ring made of chemical-resistant rubber is applied to minimize the gap in the joint, and this O-ring is the first to be gradually damaged, leading to a leak accident. Although these leaks are not frequent, they do occur unexpectedly, and there is a problem that can lead to not only huge property damage due to the interruption of the manufacturing process, but also human accidents. Therefore, to prevent this, a system that can detect minute leaks of hazardous chemicals in advance and notify the manager is required.

MICROVIBRATING

MICROSEISM

vibration, pulsation,corrosion, and hardening

-

Toxic gases and chemicals gradually corrode the sealing of the pipe connection part and the O-ring inside the clamp, weakening the durability in the hardened state, and leaking after cracks occur.

-

Leakage of poisonous flammable gas and chemicals occurs after micro-distortion of the pipe joint due to vibration and pulsation inside the pipe

-

Huge

cost loss -

Human

casualties -

decline in corporate

reputation

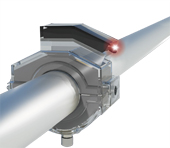

EXISTING

USING CLAMP

To solve this problem,

a clamp is installed on the pipe connection part.

The clamp prevents loosing of pipe joint,

avoiding gas and chemical leaks

However, poisonous and flammable

gas/chemical cannot even seal

the pipe joint and block the O-ring

inside the clamp.

The fine gap between the clamp and O-ring

causes gas/chemical leaks due to vibration,

pulsation, and chemical reaction.

-

Before Gas/Chemical leaks

-

After Gas/Chemical leaks

Most of the clamp products are certified by various organizations and distributed on the market, but the certification standards are not keeping up with the pace of development of the high-tech industry.

LIMITS OF

CLAMP IN MARKET.

we need the right product

-

Endurance limit

Endurance limitThe sealing of the pipe joint and even the internal O-ring cannot be blocked

-

Actions after damage

Actions after damageGas/chemical leak signal must occur over a certain range

-

Difficulty removing leaks

Difficulty removing leaksAs harmful gas/chemicals has already spread around the pipe joint, It is difficult to remove

-

Arbitrary release problem

Arbitrary release problemThere is a risk of accidents because the device can be released arbitrarily

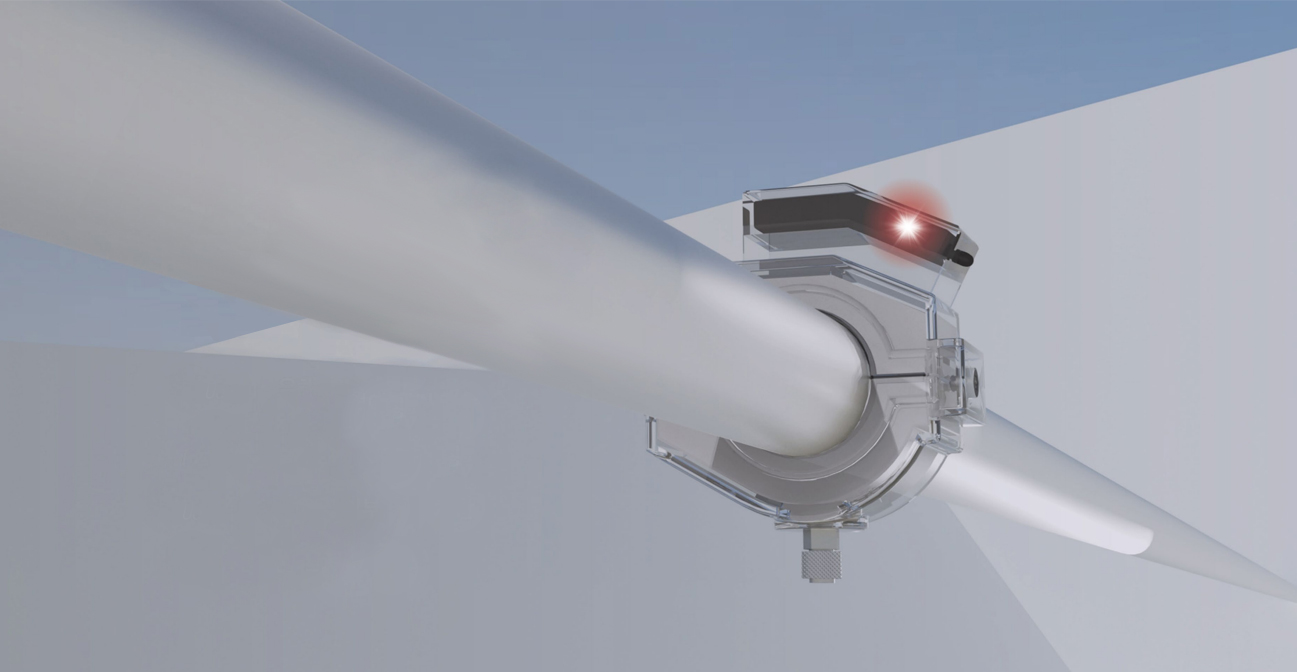

OBTECT OVERVIEW.

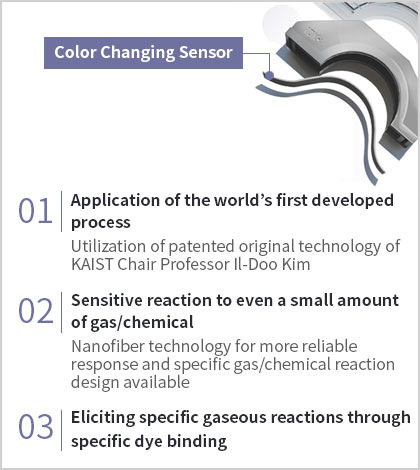

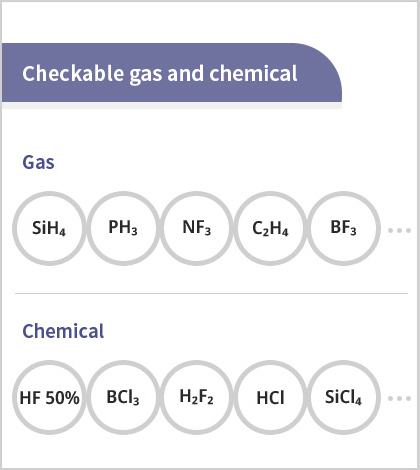

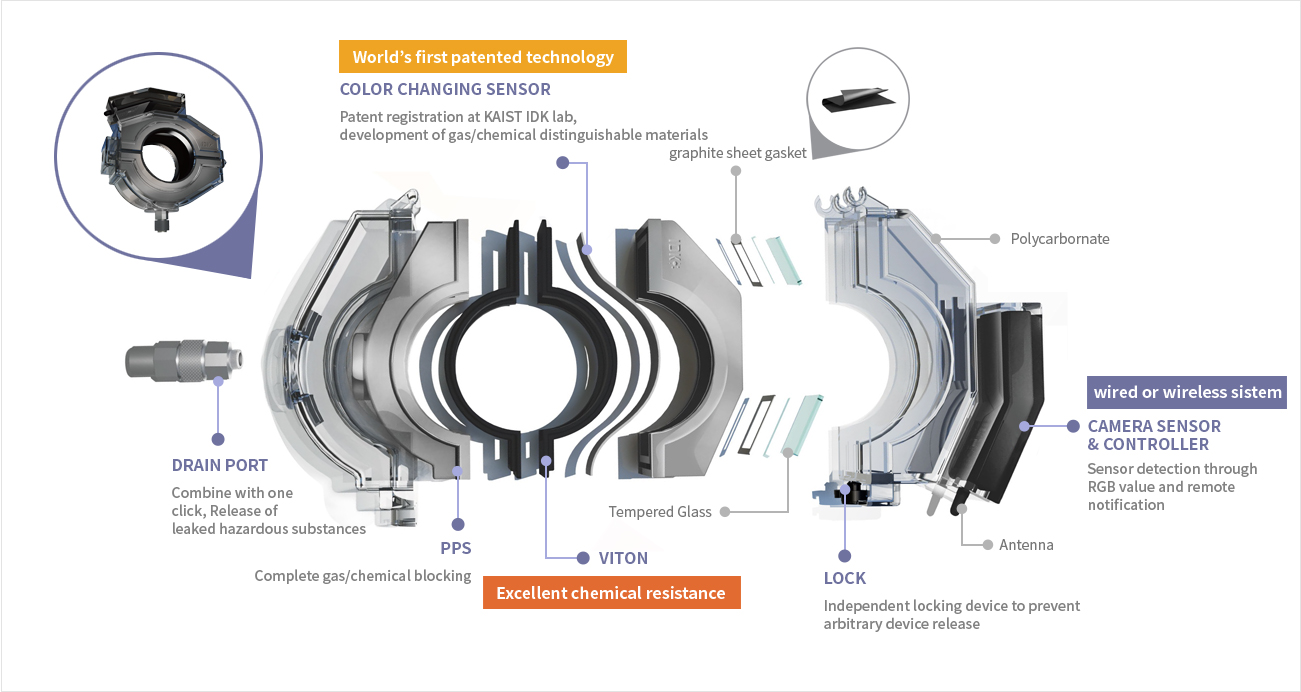

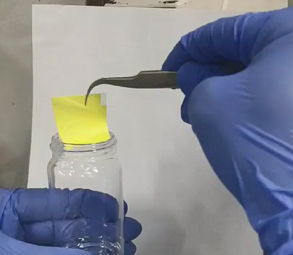

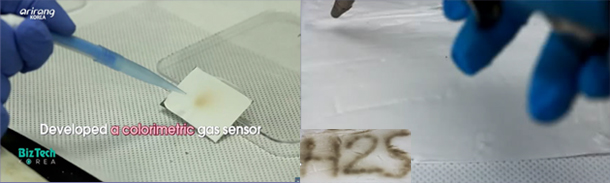

COLOR CHANGING

SENSOR.

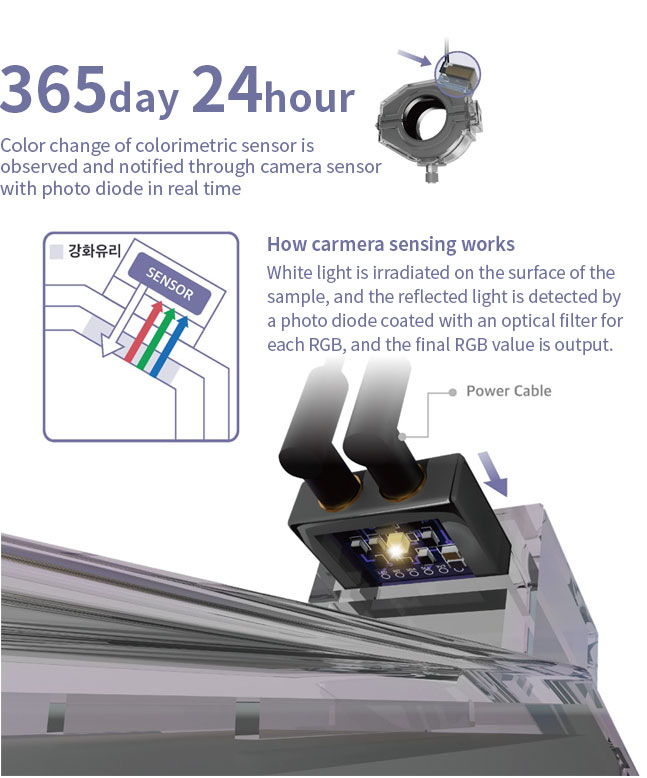

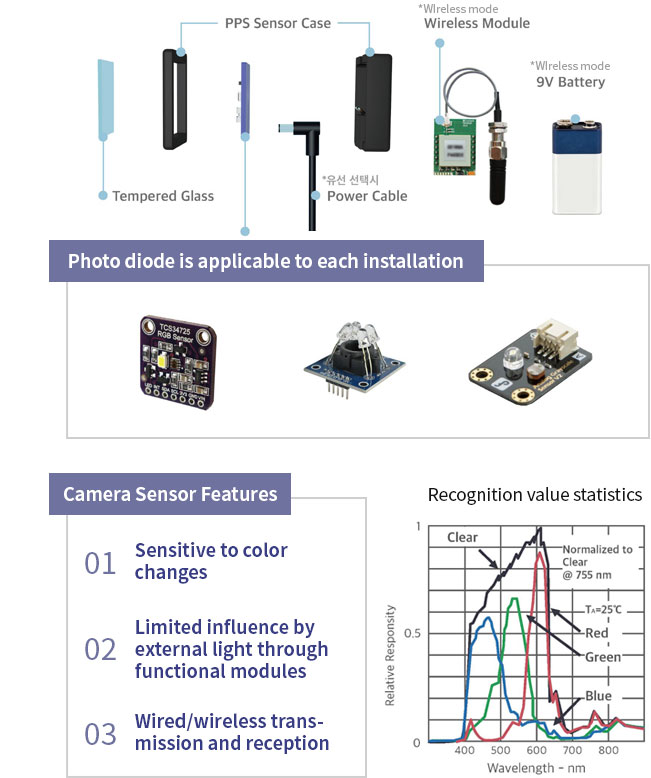

CAMERA SENSING.

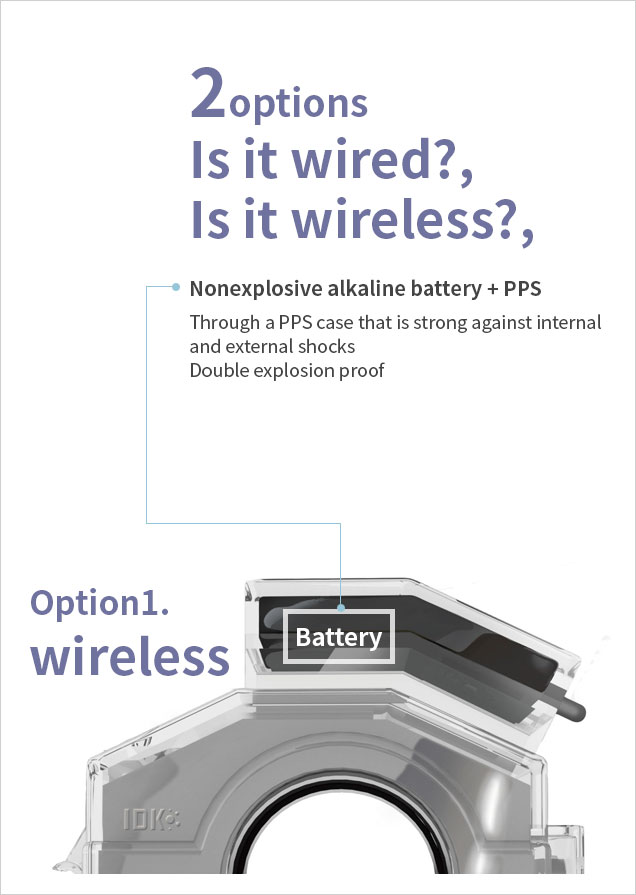

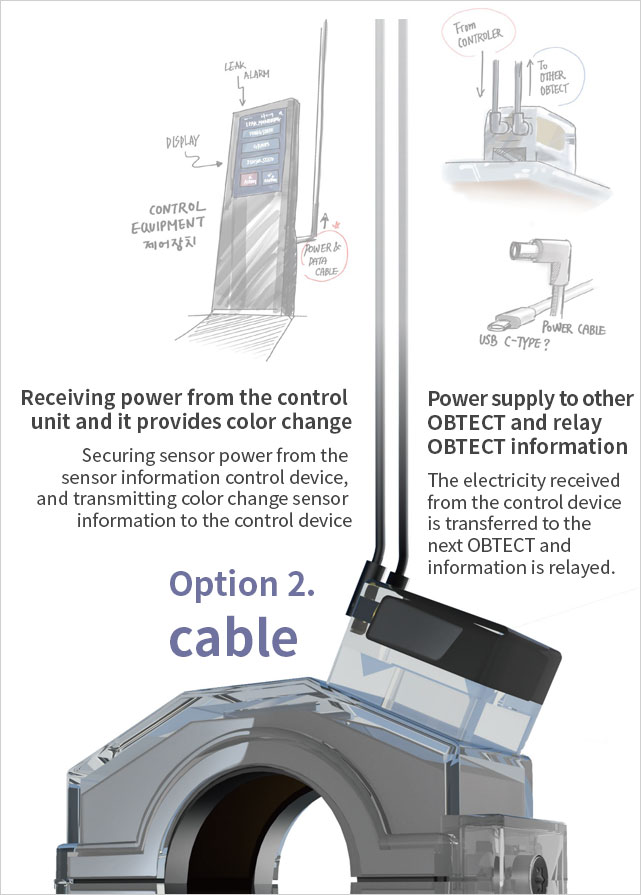

CABLE OR BATTERY.

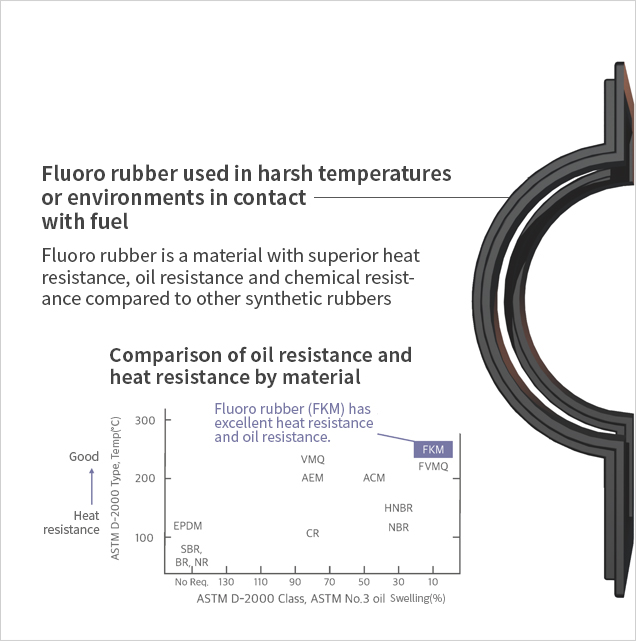

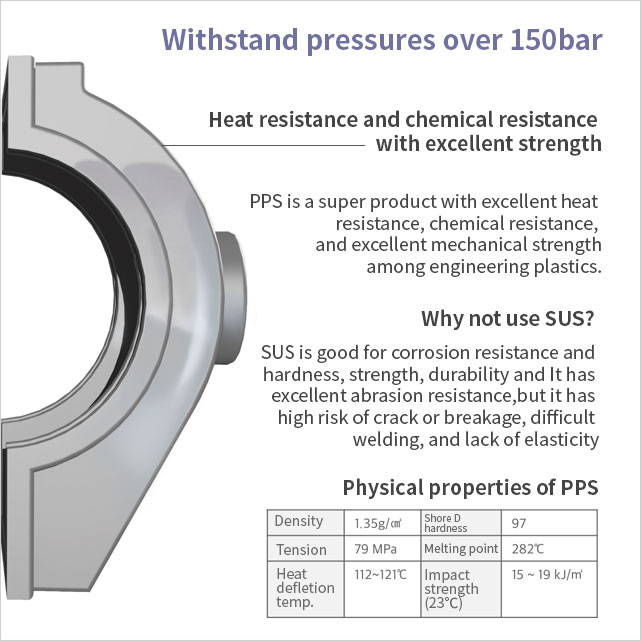

HIGH DURABILITY

OF VITON & PPS.

720

hours more than

Leak containment of gas and

chemical as hazardous substances

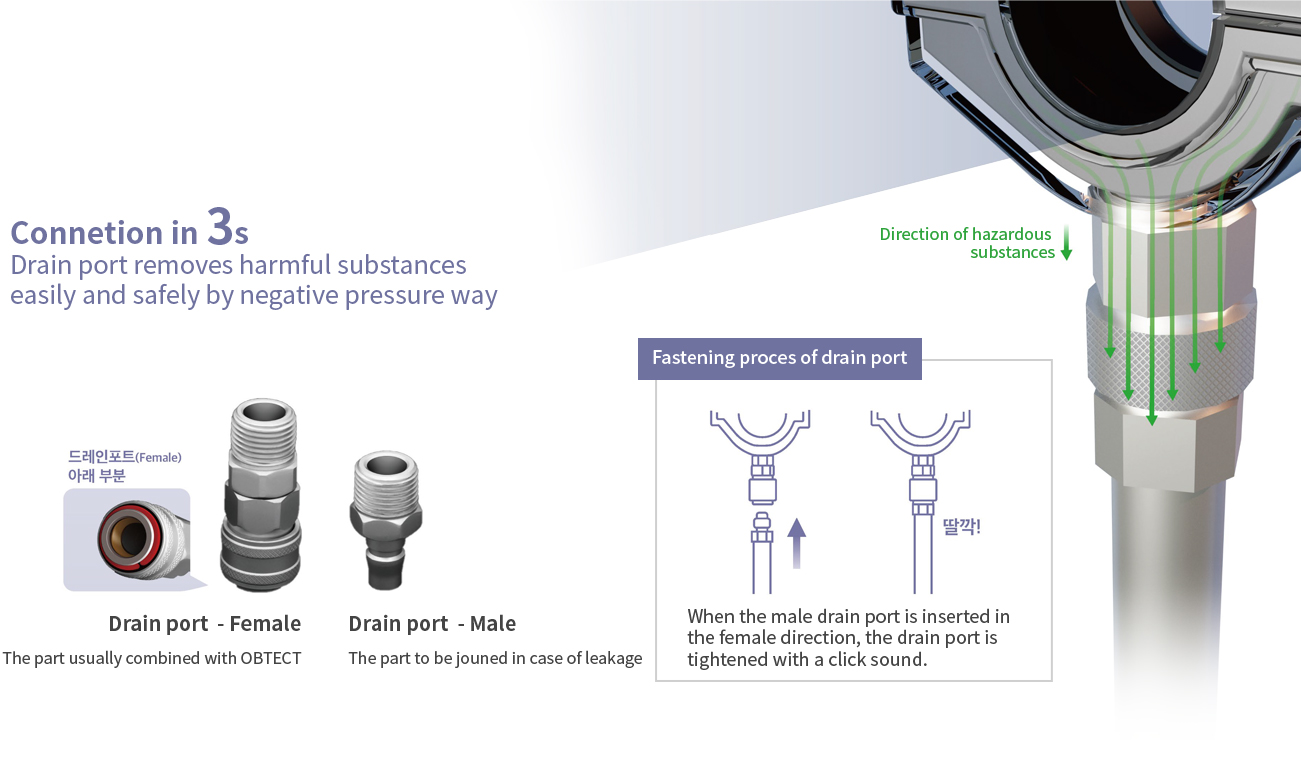

DRAIN PORT.

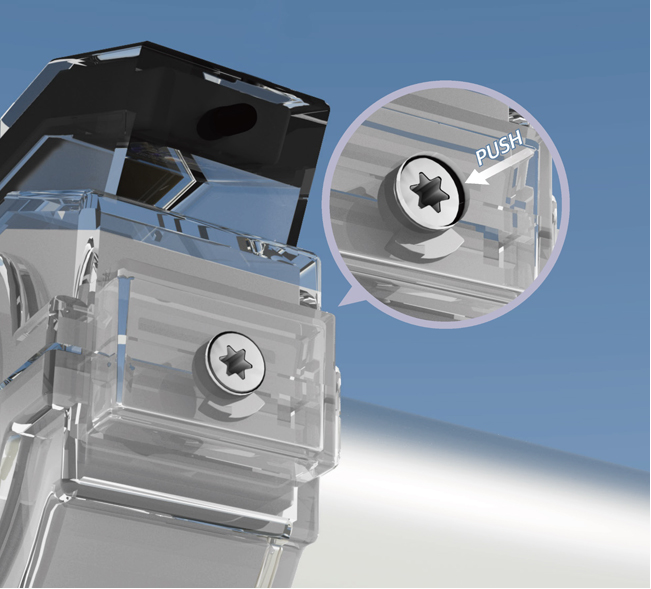

LOCK

arbitrarily by anyone other than the

authorized person

Prevent the spread of damage and maintain safety

and confidentiality

A locking device made using proprietary technology prevents

damage from spreading due to leaks, protects users,

and maintains confidentiality.

-

01Push after combining

01Push after combining

the dedicated key -

02Rotate clockwise

02Rotate clockwise -

03Top polycarbonate case open

03Top polycarbonate case open

SENSING PROCESS.

The OBTECT controls the leak situation with the

control equipment as follows.

Through this, unlike in the past, it is possible to

clearly identify and control the leak situation.

leak status, notification of leak

occurrence and location confirmation

color change sensor to removal

of harmful substances through

the drain port

-

01Change of colorimetric sensor

and operation of optical sensorWith gas/ chemical leaks Color of the sensor progress

-

02Signal transmission

to control equipment after optical

sensor reaction

-

03Understanding the situation with control equipment By identifying the signal transmitted from the sensor, it notifies that a leak has occurred and iden- tifies the location of the leak. (P&ID applied)

-

04With tempered glass, check for actual leaks

Visually observe the color variation to check for leaks once more

-

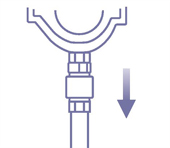

05Gas/chemical emissions through drain port

Poisonous and flammable gas/chemical in the leaking pipe connection part are removed safely through the drain port

CONTROL

EQUIPMENT.

-

Intuitive UX/UI OBTECT

control unit check the

status of OBTECT and the

pipe connection part.

UX/UI configuration for easy

understanding,

OBTECT notification that a leak

occurred by detecting the signal of OBTECT

-

1,000:1

1,000 OBTECTs with

one control device -

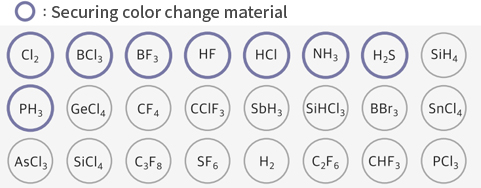

COLOR SENSOR

- · No product could ever before

- · High-speed, high-sensitivity response

- · 3D porous nanofiber technology

NO PRODUCT

COULD DO

EVER BEFORE.

-

Real-time development of

toxic gas/chemical detection

color sensor materials -

Technology innovation of

color sensor Toxic gas

detection library is presented

Gas/Chemical classification

possible

Real-time detection as

well as safe discharge of

hazardous substances

| Manufacturing company |

GIF KOREA | American Gas & Chemical |

ROCOL (Part of ITW) |

Nitto |

|

|---|---|---|---|---|---|

| Country | South korea | U.S.A | U.K | Japan | South korea |

| Detection method |

PH responsive Taping method |

Gas detectable dye responsive |

Spray method | Gas detectable dye responsive |

Nanofiber based Gas detectable dye responsive Direct connection to the pipe or joint |

| Sensing material |

Acid and base (liquid) | Cl₂, NH₃, H₂S, CO | Cl₂, NH₃, H₂S, CO | NH₃, H₂ |

14 or Gas, Chemical |

| Performance and feature |

Detection limit Reaction time Suitable for liquid phase reactions but limited gas detection |

Detection limit Reaction time Expensive |

Detection limit Reaction time No real-time detection |

Detection limit Reaction time |

Sensitive detection |

| Product image |

|

|

|

|

|

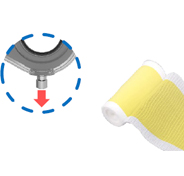

FAST CHANGING,

SENSITIVE REACTION

-

Before color change

-

After color change

3D POROUS NANOFIBER

TECHNOLOGY - PATENTED.

-

Completion of production facility nanofiber

alignment electrospinning machineEstablishment of facilities for mass production

of 3D porous nanofiber color change sensor -

1/10of a spider's web

0.3μm(micrometer)

Complete prevention

and control of leaks.

-

01

Can be installed without linestop

-

02

Real-time LEAK monitoring

-

03

Blocking external leakage

-

04

No need to report leaks

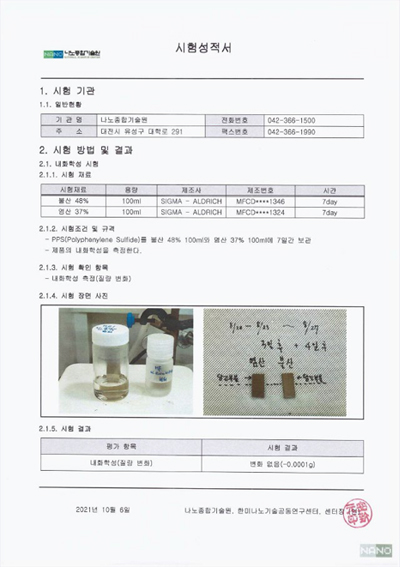

APPENDIX.

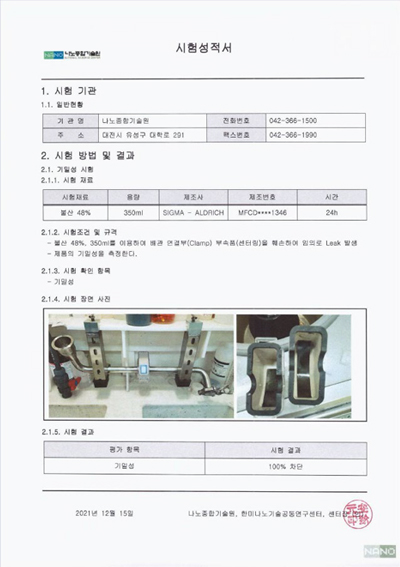

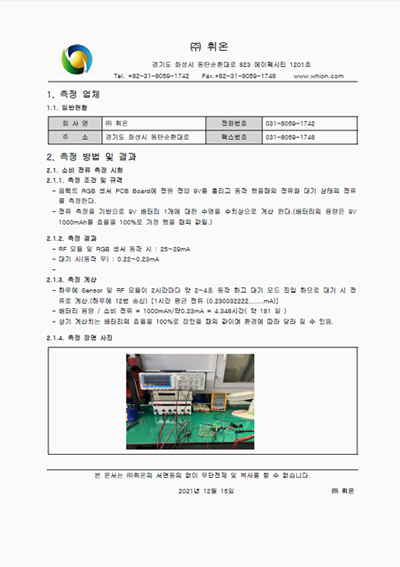

Proof of product excellence through test reports

-

PPS chemical resistance test NNFC

-

OOBTECT performance test NNFC

-

Camera module performance test